Construction without destruction

Conventional building methods have taken too much from the natural world for far too long. It’s time to start giving back to create a future where everyone – and everything – can live better.

We are combining low embodied-carbon materials with modern construction methods to transform the industry. Our work in materials technology, digital tools and building physics combine to offer a groundbreaking alternative to existing construction methods.

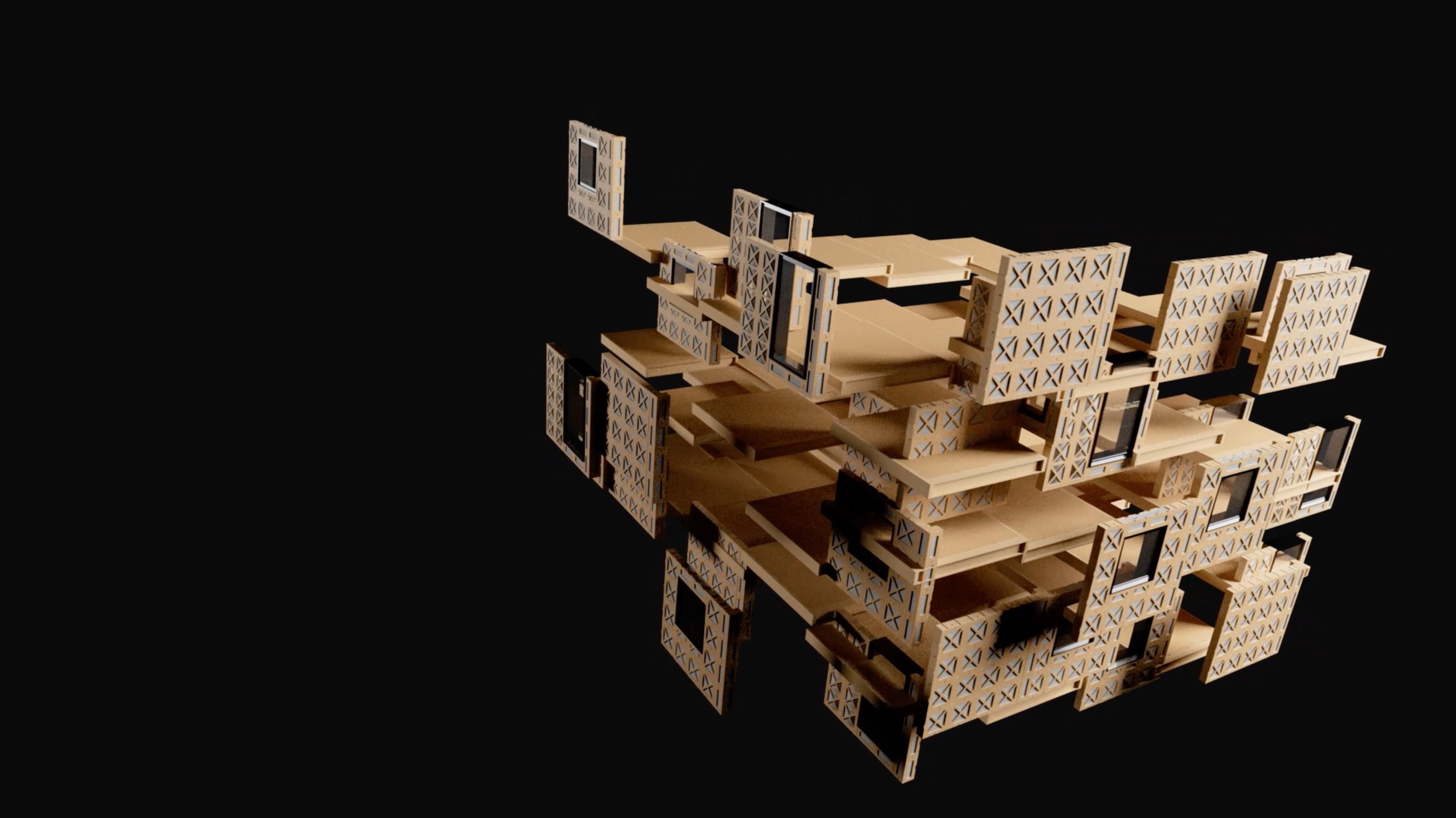

Informed by three years of intensive R&D, we have designed a comprehensive construction system made exclusively from climate-neutral materials. It’s a breathable, high-performance thermal envelope, floor, roof and internal walls, where all parts are individually demountable so they can be adapted, reassembled and reused.

Building with regenerative materials such as hemp and timber means the carbon captured as they grow exceeds the embodied carbon created from harvest, processing and production. Our buildings remove more carbon from the atmosphere than it takes to make them, and are more energy efficient, healthier and more comfortable places to be.

The problem

The built environment is responsible for 38% of global carbon emissions, with 11% directly from the manufacture of construction materials and products. These embodied emissions have a major impact on global heating because they occur upfront, while savings due to energy efficiency are spread over decades. In the UK, construction, demolition, and excavation account for 60% of material use and waste generation.

Alongside these clear sustainability challenges, modern conventional buildings have poor air quality that’s bad for people’s health. They are increasingly airtight, overheat in summer, and volatile organic compounds are released from a wide range of mostly petrochemical-derived materials.

We need a radically different approach to the way buildings are designed and built.

The solution

We have reimagined the entire life of buildings, including:

the way regenerative materials are grown, harvested and processed

how buildings are conceived, designed and constructed

how we use, maintain and adapt them

how buildings no longer required can be easily disassembled and reused elsewhere.

This is why we’re different:

1

Construction efficiency

We use digital tools to standardise parts and reduce lead times, cost, and waste, without compromising design flexibility.

Site assembly is rapid without needing specialist contractors.

2

Construction performance

The thermal mass of our lightweight panels performs as well as dense, high-carbon alternatives.

Thermal and vapour buffering reduces energy use and summer overheating, and improves moisture control, indoor air quality and building fabric durability.

3

Material efficiency

Panels and components are made from non-toxic, climate-neutral materials. Using hemp as primary insulation encourages local production of short-cycle carbon capture crops, and factory-controlled production reduces waste.

A lightweight superstructure reduces substructure embodied carbon and costs.

4

Circular economy

Individual panels are demountable so they can be repositioned and reassembled in different configurations, allowing buildings to be adapted without waste.

Following circular economy principles, there’s no waste when the building reaches the end of its life either, because panels can be disassembled and reused elsewhere.

5

Whole life carbon

Our materials capture more carbon than the upfront embodied carbon of production.

Together with a high-performing thermal envelope to reduce operational energy use and rigorous circular economy strategies, our buildings ultimately absorb more carbon from the atmosphere than it takes to make them.

Zero waste

Designed for disassembly and adaptation, allowing zero waste alterations and re-use.

Regenerative building solutions are not only possible, but perform better, last longer and cost less than conventional construction methods.

Who we are

Our multidisciplinary team includes construction experts, architects, engineers and material scientists. We came together to make buildings more affordable, healthier, use less energy, and have a positive impact on climate change and society.

Chloe Donovan

Managing Director

Jessica Stanton

Finance and Operations

Assistant

Nigel Wong

Design Assistant

David Nicholson

Director of Design

Krista Zvirgzda

Operations Manager

Dr Mike Lawrence

Director of Research

Melissa Wicks

Operations Assistant

Sam Hogg

Research Chemist

Annie Benton

Industry Engagement Manager

Peter Walentowicz

Workshop Assistant

Pete Forster

Mechanical Engineer

Chris Martin

Workshop Assistant

Rosie Donovan

Workshop Coordinator

Tasha Greenfield

Design Coordinator

Graeme Jones

Workshop Supervisor

The principles of Circular Economy are central to how the carbon footprint and wider environmental impacts of the built environment can be reduced.